The electronics business depends on CNC machining to the creation of elements and components which make up several buyer and industrial electronics units. CNC machining is used to generate circuit boards, housings, connectors, together with other important factors that call for superior precision and intricate layouts.

Complexity: When CNC machines can handle intricate geometries and patterns, component complexity can affect generation time and charges. As the complexity of a component will increase, some time used on organising and programming the equipment also will increase, resulting in for a longer time guide times and most likely larger costs.

With a chance to work on numerous axes, CNC mills present you with a significant standard of flexibility for purposes starting from aerospace elements to professional medical products.

Brass is undoubtedly an alloying consisting of both copper and zinc. The gold products is actually a weather conditions- and corrosion- resistant metal with tensile energy comparable to moderate steel. It is also an very easy to equipment product, so feedrates can keep on being higher and coolant want is nominal.

Then, following some time, you're going to get your sections all set to use since the CNC turning Centre completes the machining procedure. Now, you are able to pull out the prototypes or parts in the CNC turning equipment system and rely on them further in the output cycles. Precision CNC Turning Procedures at TEAM Rapid CNC turning center is adaptable and can make round or cylindrical parts. They are able to do the job in a variety of procedures and rapidly adapt to different product forms. Other procedures is usually used to make different types of CNC-turned elements. These strategies is often formulated for various stop-uses, which includes multi-perform turning, multi-section turning, swiss-style turning etc.: Multi-functionality Turning Machining As read more the most effective CNC turning factors producers, CNC lathes are capable of substantial-pace milling and turning at Crew Swift, which can easily take care of the machining design's complexity in the CNC machining system. Multi-section Turning Machining Superior CNC turning and milling abilities let speciality lathes to show several sections at the same time. A essential characteristic is adaptability within the path and axis to help synergy from the art movement.

Soon after preparing the types in CAM structure, the next stage consists of putting together the machine. This generally contains calibrating the device applications and securing the workpiece onto the machine. The choice of equipment equipment relies on the fabric from the workpiece and the final element’s design and style.

CNC machining’s overall flexibility permits the production of numerous part geometries according to the precise necessities of different industries and purposes.

CNC machining is really a manufacturing approach that works by using computerized controls to work and manipulate equipment applications, shaping several different supplies into tailor made elements and layouts.

Call us at RapidDirect to find out how we could help your production plans with precision and dependability.

Yow will discover a number of methods beneath, or you could head to our expertise hub and filter on CNC machining circumstance scientific studies, in-depth structure recommendations, and explanations of various surface area finishes.

Speedy ahead to right now and present day CNC turning machines are controlled numerically and with no need for continual manual supervision.

One of several major benefits of CNC machining is its pace and scalability. The method is faster than manual machining mainly because of the automation of milling, turning, or EDM machines.

CNC machining is superb for producing a certain batch of goods, nonetheless it is probably not economically feasible for big creation runs. This limitation is due to the superior setup fees and some time required to configure machines for every new task.

CNC Turning CNC turning is usually a process of machining elements with cylindrical capabilities from steel or plastic rod stock.

Patrick Renna Then & Now!

Patrick Renna Then & Now! Christina Ricci Then & Now!

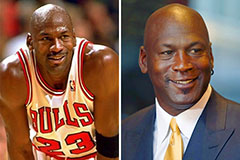

Christina Ricci Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now!